Cathode Ray Tube Clock

Introduction

This page is to describe my first experiments to etching a brass plate to decorate a front/top panel for a clock (described in detail here).

Steps…

I used the same equipment and chemicals to etch the brass plate that I use to make PCBs. The process is more or less the same although the early steps don't apply as I tend to by the PCB already coated with a photoresist.

This description is intentionally brief. If you have the equipment and know how to etch PCBs it will all be very clear to you. I'm not going to waste your time.

- The 2mm thick brass plate was bought on ebay

- Brass plate was cut to size - 100mm x 150mm in this case

- The plate was thoroughly cleaned - I used a domestic mildly abrasive surface cleaner

- The plate was degreased using xylene (I wore nitrile gloves so as not to leave any finger grease on the surface)

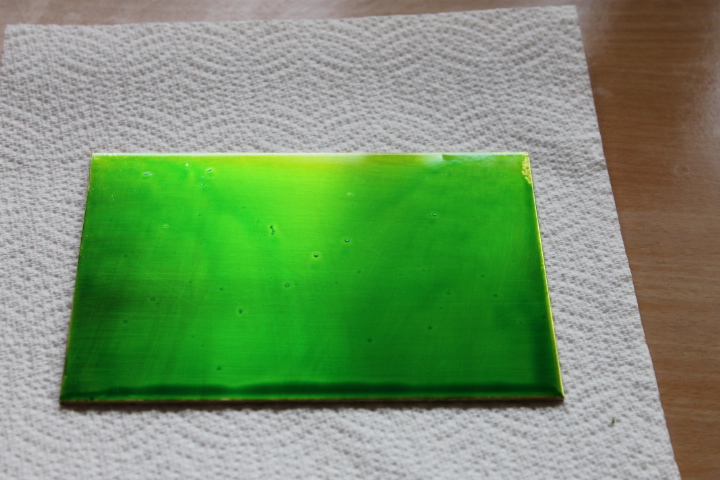

- The plate was sprayed with photoresist which was allowed to dry (in a dark, warm place for a few hours)

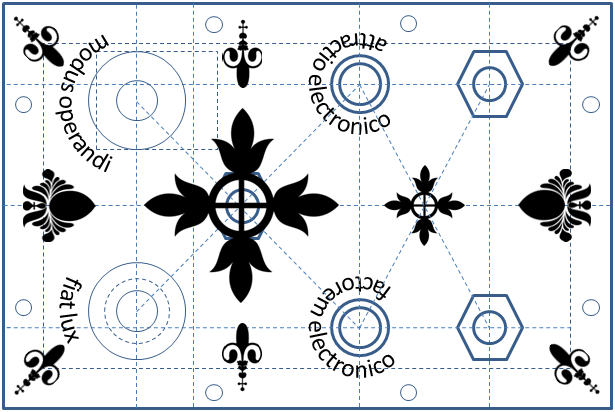

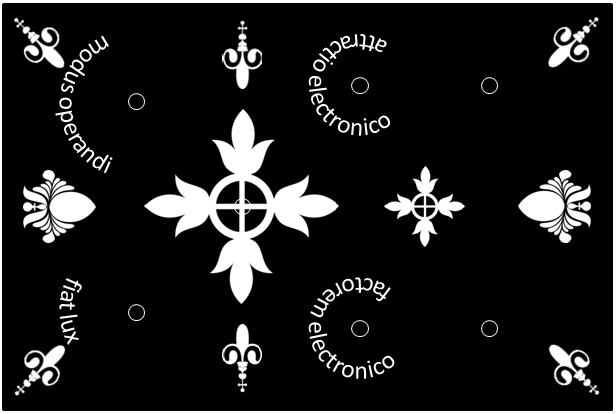

- I created the image mask:

The mask image was printed onto laserjet film using my trusty HPLJ4 printer

- The photoresist coated brass was exposed to UV through the film image (the process is now very similar to making PCBs) on a UV lightbox

- …and then developed

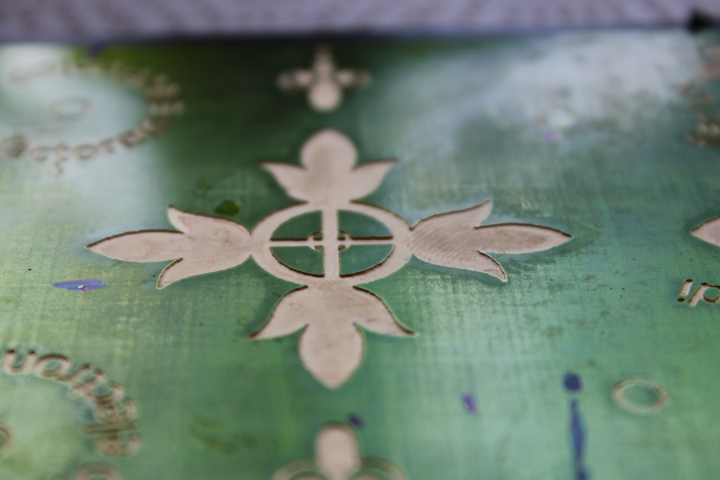

- The developed brass plate was check for defects (the extra dots and lines on the plate in the image gallery below, show where I used a resist pen)

- The edge and back of the plate was protected using PVC tape to prevent unwanted etching

- The plate was etched in sodium peroxodisulphate, "clear etch" which I use in preference to ferric chloride - more expensive but not as messy. Because I wanted an etched depth much greater than the thickness of copper on a PCB, the etching time was much longer - nearly an hour to get the etched depth I judged suitable for painting (see photo gallery close up)

- I removed the PVC tape and then plate was washed, dried and painted with spayed on matt black paint

- After drying, I sanded down the paint using a flat sanding block to remove the surface paint but leave the etched areas filled with paint. I used wet and dry paper from about 400 to 2000 grade to get a smooth finish.

- From now on I again only handled the plate using nitrile gloves as I did not want any finger marks to appear. When the rest of the brass and copper components had be made and cleaned and the components assembled, I coated the metals with sprayed clear lacquer

Considering this was my first attempt at brass etching, and I used equipment and chemicals I already had to hand (only the brass plate and photoresist were bought for this project), I am more than pleased with the results.